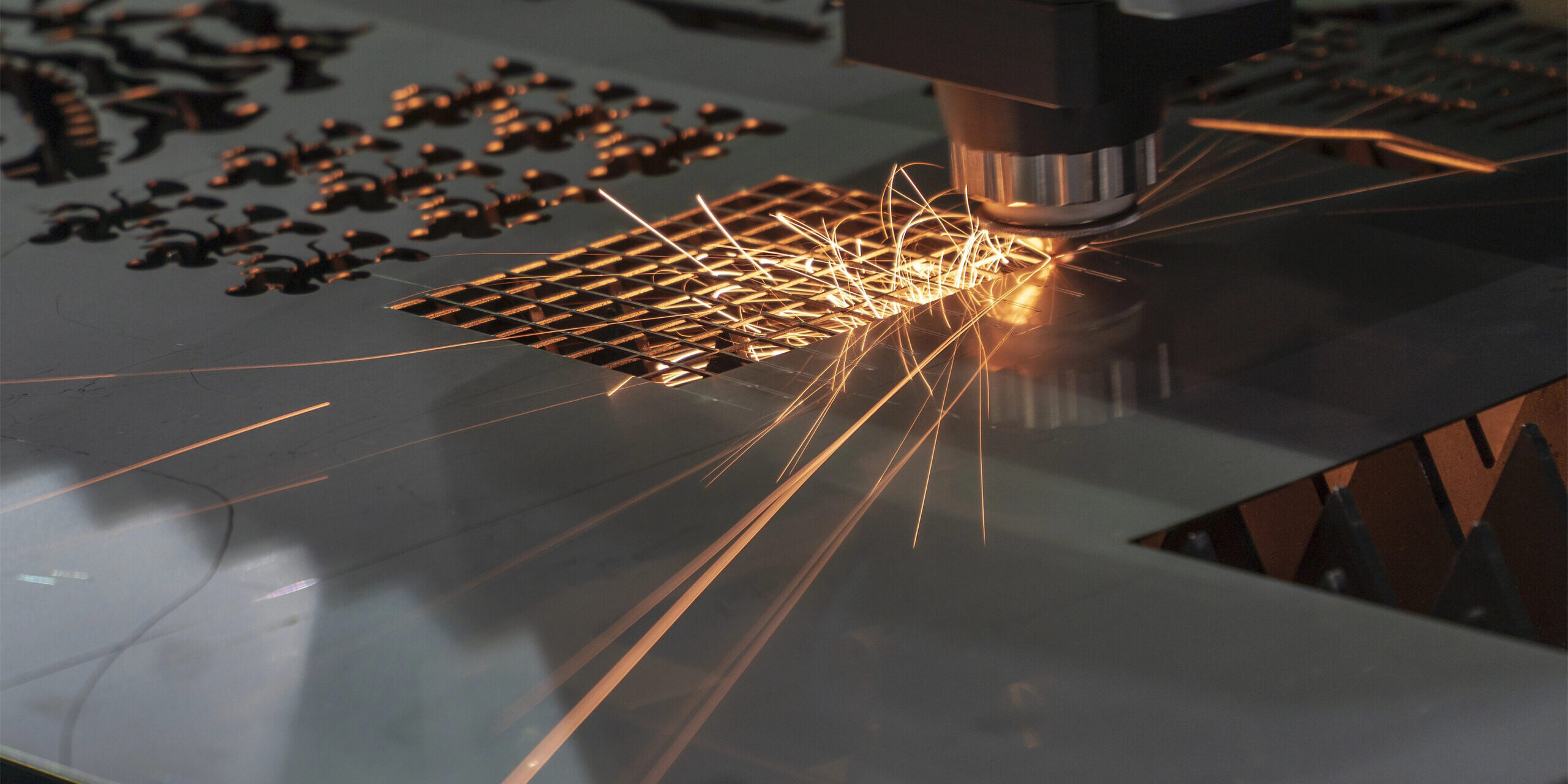

In the world of metal fabrication, precision is everything. Whether you’re cutting intricate parts for an aerospace component, clean lines for a modern architectural design, or tight tolerances for industrial machinery, there’s no room for error. That’s where fiber optic laser cutting shines.

Fiber lasers are a major advancement in the industry. Compared to traditional cutting methods or even older CO₂ laser technology, fiber lasers offer unmatched precision, speed, and efficiency. They’ve quickly become the gold standard for high-accuracy metal cutting jobs, especially when quality, consistency, and turnaround time matter.

Here’s why fiber optic laser cutting is ideal for high-precision projects—and how it’s raising the bar for custom laser cutting services, custom metal solutions, and custom metal fabrication.

1. Precision Cutting for Thin-Gauge Materials

Fiber lasers are uniquely suited for cutting thin-gauge metals. Their beam is narrower and more concentrated than other types, allowing for incredibly fine, detailed cuts. This is especially beneficial for industries that depend on complex components or delicate metalwork—electronics, automotive, and medical equipment manufacturers, to name a few.

Thin metals can be tricky. With mechanical cutting or even plasma methods, you’re more likely to deal with warping or edge deformation. Fiber lasers avoid this by generating less heat and using a non-contact process. The result? Clean, precise cuts with minimal distortion.

For custom metal fabrication jobs that involve stainless steel panels, aluminum enclosures, or small brass components, fiber laser cutting ensures consistency from the first piece to the last.

2. Cleaner Edges with Less Post-Processing

Another major advantage is the quality of the cut itself. Fiber optic lasers produce extremely smooth edges, even on materials that are notoriously tough to work with. Whether it’s mild steel, aluminum, copper, or brass, fiber lasers deliver clean cuts with minimal burrs.

This reduces or even eliminates the need for secondary finishing processes like grinding, sanding, or deburring. That’s a big win for efficiency and cost savings. It also guarantees that the final product has a polished appearance and is professional straight off the machine.

For custom laser cutting services, this level of finish is a strong selling point. Customers want high-quality parts that are production-ready, not rough prototypes that need extra work. Fiber lasers help fabricators deliver exactly that.

3. Ideal for Reflective and Non-Ferrous Metals

Traditional CO₂ lasers struggle with reflective materials like brass, aluminum, and copper. The reflected light can damage the laser source, and the inconsistent absorption of the beam often results in uneven cuts.

Fiber lasers, on the other hand, are much better suited for these metals. They operate at a different wavelength (around 1 micron compared to 10 microns for CO₂ lasers), which is more readily absorbed by reflective surfaces. That means cleaner, faster cuts with fewer complications.

This makes fiber laser technology a must-have for any shop offering custom metal solutions across multiple industries. When you need to cut aluminum housings, copper contact points, or brass panels with precision and consistency, fiber lasers are a clear choice.

4. Speed and Efficiency for Production Jobs

Fiber lasers aren’t just accurate—they’re fast. They cut through thin and medium-thickness materials at significantly higher speeds than CO₂ lasers or plasma cutters. This makes them ideal for high-volume jobs where efficiency is key.

The system itself is also more energy-efficient and requires less maintenance since fiber lasers have fewer moving parts and don’t rely on mirrors or gas mixtures. This results in lower operating costs over time.

When you’re running large production orders under tight deadlines, every second counts, with fiber lasers, you can maintain speed without compromising precision—something that’s critical for large-scale custom metal fabrication projects.

5. Automation-Friendly and Scalable

Modern fiber laser systems are built with automation in mind. They integrate easily with robotic loaders, CNC controls, and smart manufacturing software, allowing shops to scale production without sacrificing quality.

This makes them perfect for everything from one-off prototypes to full-scale manufacturing runs. Whether your business is just starting to offer custom laser cutting services or you’re scaling up your existing operation, fiber lasers help you do more with less.

Automation also adds another layer of consistency, which is crucial when every part needs to meet the same high standards.

6. Versatility Across Industries

Because fiber lasers handle such a wide range of metals and thicknesses, they’re used across countless sectors—automotive, aerospace, electronics, architecture, medical devices, and more.

This level of versatility allows custom fabricators to expand their offerings and take on a broader range of projects. If your clients need precise cutouts for a control panel one day and decorative aluminum signage the next, fiber laser technology ensures you’re always ready.

Final Thoughts

Fiber optic laser cutting is more than just a trend—it’s the future of precision metalwork. With better edge quality, faster processing times, and the ability to handle even the most challenging materials, fiber lasers are redefining what’s possible in custom metal fabrication.

Looking for custom laser cutting services that deliver clean, consistent results every time? Connect with Abraham Steel today!