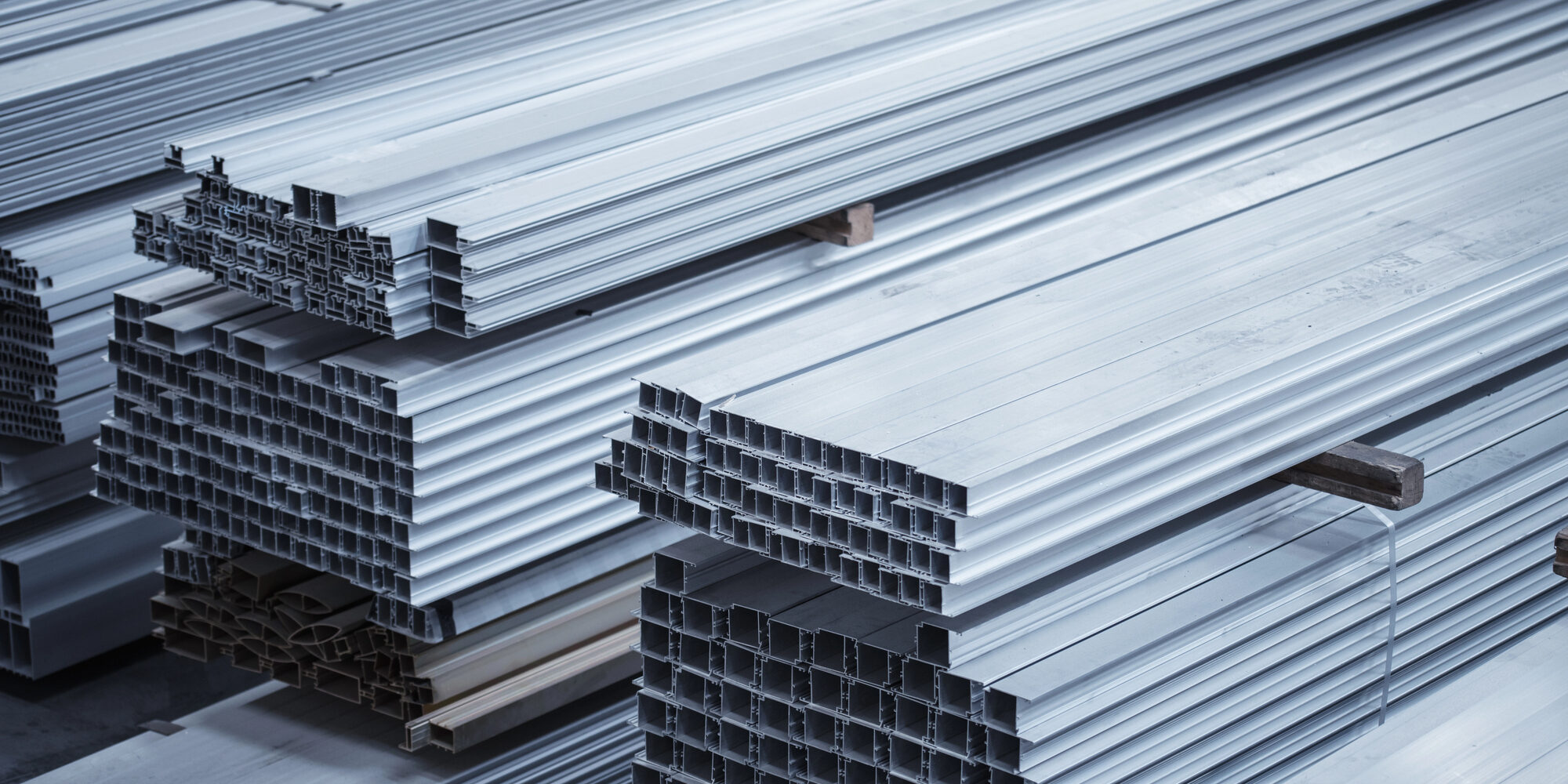

When people think about tough metals, they picture steel or iron. But there’s another contender quietly dominating job sites and fabrication shops: aluminum. Contractors and metal fabricators are turning to aluminum metal works more than ever—and not just for its sleek appearance. It’s lightweight, strong, corrosion-resistant, and adaptable across a wide range of applications.

Aluminum doesn’t just show up. It performs.

Lightweight—but Not Light Duty

One of the biggest reasons aluminum is gaining ground in commercial metal fabrication is its weight—or lack of it. Aluminum has a weight that is approximately one-third that of steel. That means it’s easier to transport, lift, and install, especially on complex job sites or in projects requiring a lot of manual handling.

Less weight doesn’t mean less performance. For contractors, that balance between ease of handling and structural integrity makes aluminum a powerhouse for everything from large commercial frames to lightweight panels and supports.

Strength That Surprises

Aluminum may be light, but it takes stress like a heavyweight. It offers high strength-to-weight ratios, meaning it can support impressive loads without the bulk. In commercial builds, that translates to reduced structural dead weight, less strain on foundations, and easier engineering without sacrificing safety.

When alloyed correctly, aluminum can rival and even exceed the strength of certain types of steel—especially when stress and vibration resistance are key. That’s why you’ll see aluminum in everything from curtain walls and window frames to bridge decking and railings.

Custom metal fabrication teams love it because it can be cut, bent, and welded to exacting specs while still maintaining structural strength. That kind of versatility cuts lead times and reduces waste—both big wins in fast-paced projects.

Built-In Rust Resistance

Unlike steel, aluminum doesn’t rust. It naturally develops a protective layer of oxide that resists corrosion even when scratched. That’s a game-changer for outdoor structures, coastal environments, or areas with high humidity and salt exposure.

In commercial metal fabrication, durability is non-negotiable. Clients want materials that last, and aluminum delivers. Whether it’s a sleek handrail on a waterfront condo or a sign frame exposed to the elements, aluminum keeps its integrity and looks sharp doing it.

This rust resistance also means lower maintenance. Fewer repairs and replacements save property owners money in the long run—and that makes aluminum an easy sell.

A Fabricator’s Dream

Aluminum is highly formable. It can be precision cut, welded, machined, and shaped with less effort than harder metals. That opens the door for true custom metal fabrication—complex shapes, detailed finishes, and tight tolerances.

Want powder-coated panels? No problem. Need custom-cut brackets for a unique architectural design? Aluminum can handle it. This makes it a favorite in both modern commercial construction and artistic or industrial design projects.

Custom metal fabrication isn’t just about making things fit. It’s about creating exactly what the project demands. And aluminum is one of the few materials that can meet that challenge at scale.

Sustainability in the Spotlight

More contractors are also looking at aluminum for its environmental edge. It’s 100% recyclable without losing quality, and recycling aluminum consumes only 5% of the energy required to produce it from raw ore.

For LEED-certified projects or any commercial build looking to cut its carbon footprint, aluminum is a strategic choice. Clients love it, architects value it, and fabricators can feel good about using it.

Sustainability isn’t a trend—it’s a requirement. And aluminum helps contractors hit those marks without compromising performance.

Real-World Performance: From Frames to Railings

In practice, aluminum is everywhere. It’s in the curtain wall systems that wrap high-rises, the custom brackets behind digital signage, the frames of rooftop walkways, and the sleek lines of balcony railings. Contractors choose aluminum because it handles exposure, temperature changes, and heavy use—all while keeping its shape and finish.

In commercial metal fabrication, where precision and performance drive the process, aluminum is proving its worth again and again. It’s not the “alternative metal” anymore—it’s often the first choice.

The Bottom Line

Aluminum works harder than most people think. It’s light enough to lift without heavy machinery, strong enough to handle stress, resistant to the elements, and easy to fabricate into just about anything.

Contractors and metal fabricators aren’t just following a trend. They’re making a smart call. When deadlines are tight, specs are complex, and performance can’t be compromised, aluminum delivers.

Whether you’re sourcing materials for your next commercial build or exploring custom metal fabrication options, it’s time to give aluminum the respect it’s earned. It’s not just part of the structure—it’s part of the solution.

Start Your Custom Fabrication Project Today

From sheet stock to polished perfection, Abraham Steel delivers high-quality results on projects of any size. Whether you need precision cutting, expert bending, professional welding, or flawless polishing — we’ve got you covered.

Contact us now to bring your custom metal solution to life with craftsmanship you can trust.